© 2024 Alliedflex Technologies Inc. | Site by Longtail Digital

Home » IXAPACK Pouch Automation

iXAPACK is a prominent French machinery manufacturer, specializing in complete turnkey secondary flexible packaging robotic automation systems, with a focus on quality construction and advanced robotic technology. The company provides complete turnkey systems including pouch pasteurization, pouch cooling, pouch accumulation, robotic pouch cartoning – tray packing and multi-pack case packing through automated palletizing. IxaPack provides automatic changeover for size changes in carton, tray (count & configuration) and case pack out.

Standup- and spouted-pouch packaging is a growing trend fueled by the movement toward sustainability, source reduction, product marketing differentiation and consumer convenience. Pouch packaging is replacing more expensive traditional metal cans, glass bottles, jars and plastic tubs. In recent years, there have been major market introductions into the frozen food, pet food, snack, bakery, dairy, confectionary, fruit puree and baby food categories.

Under this agreement, ALLIEDFLEX® Technologies, Inc. is the exclusive North American representative, including Canada and Mexico for the iXAPACK Pouch & Flexible Packaging Automation Program.

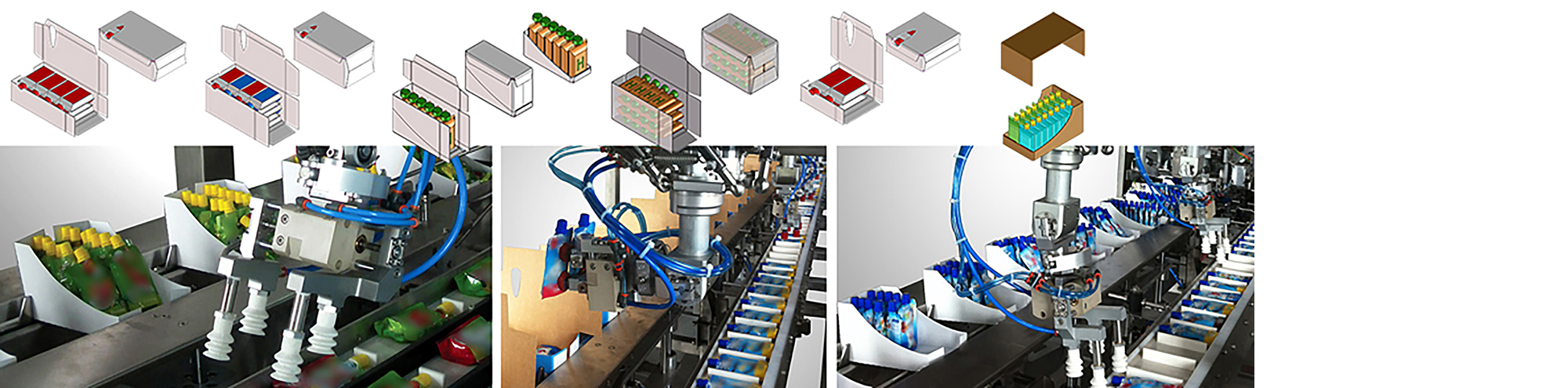

CARTONER

With a design and a manufacturing by iXAPACK, this cartoner allows forming cartons from pre-glued blanks, it introduces automatically the products (sachet, trays…) by pusher or drawer and it closes the carton.

It is available in several versions

TOP LOAD CARTONER

With a design and a manufacturing by IXAPACK, the Top Load cartoner allows forming cardboard packaging from flat blanks, it introduces automatically the products with one or several tripods robots and it closes wrap carton or display.

A first flexpicker permits, continuously, the picking and the formation of the blank before the filling by using one or several delta flexpickers. Once the blank loaded a gluing and pressing gantry permits in continuous, the carton formation and the squaring.

Our Top Load cartoner is designed in order to make it easier the operator’s work. Indeed, its ease of use and its great flexibility permit a quick format and gripper changeover.

SLEEVING MACHINE

The sleeving machine permits, continuously, to lay a sleeve around a product or a products batch, prepared beforehand, with a gluing from below. A first flexpicker permits, continuously, the picking and the formation of the blank before the filling by using one or several delta flexpickers. Once the blank loaded a gluing and pressing gantry permits in continuous, the carton formation and the squaring.

Our Top Load cartoner is designed in order to make it easier the operator’s work. Indeed, its ease of use and its great flexibility permit a quick format and gripper changeover.

TOP LOAD SLEEVER MACHINE

With a design and a manufacturing by iXAPACK, our Top Load sleeving machine STL allows, continuously, laying a product or a products batch on a sleeve, with a gluing from above. The Top Load sleeving machine offers the possibility to over-pack different type of products: trays, cans, yogurts, pots… These different products could be taken in charge by a simple and a quick tool changeover on the tripod robot. The products could be detected by cells or by vision systems permitting also the quality control.

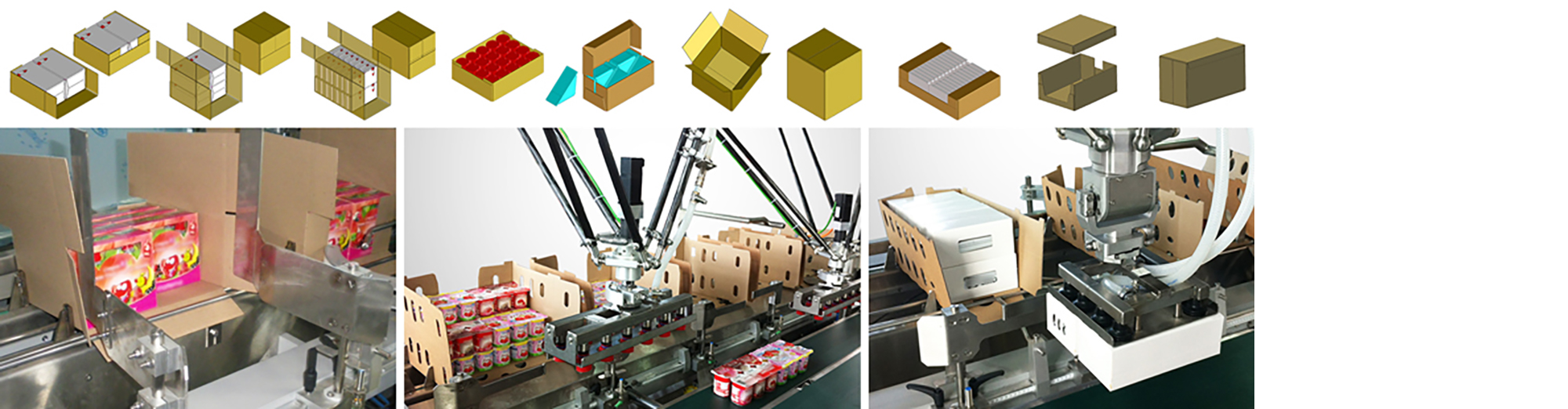

TRAY ERECTOR

The tray erector permits, from a flat blank, the formation and the gluing of 4 glued corners tray or shoulder tray. Without piston, this machine offers a great flexibility and a high speed in the format changeover with a level of cases exit of 800 mm from the ground. The used technology gives a great compactness and a good usability for the operator.

CASE PACKER

With a design and a manufacturing by iXAPACK, our case-packer « pick & place » is designed to form cardboard packing from flat blanks, it introduces automatically the products using one or several flex pickers and closes the case. Our case-packer is designed in order to make it easier the operator’s work. Indeed, its ease of use and its great flexibility permit a quick format and gripper changeover.

The case-packer iXAPACK gives the possibility of mixing the loading of the products: different tastes, forms or containers in the same case.

POLY-ARTICULED PICK & PLACE UNIT

With a design by IXAPACK, the flex-picker permits the gripping and de-stacking of flat blanks before their forming and filling. Its 3 or 4 axles provide a great flexibility in relation to the cardboard blank form.

TRIPOD PICK & PLACE UNIT

With a design by IXAPACK, the pick & place tripod unit permits a great flexibility and a high speed of functioning in its application. Several versions are available: 3, 4 and 5 axis with a load up to 8 kg.

ROBOT PALLETIZER

The robotized palletization block can admit until 5 lines of production and high speeds. According to the speeds, this machine can deposit the products on the pallet by simple gripping, by row or by layer. The interleaves and pallets picking up and setting down can be done by a gripping system or by peripheral equipment.

LAYER PALLETIZER

This compact palletizer is more used for low speed. According to the speeds, this machine can deposit the products on the pallet by simple gripping, by row or by layer. The interleaves and pallets picking up and setting down can be done by a gripping system or by peripheral equipment.

PRODUCTS CONVEYING

CASES CONVEYING

PALLETS CONVEYING

iXAPACK is a prominent French machinery manufacturer, specializing in complete turnkey secondary flexible packaging robotic automation systems, with a focus on quality construction and advanced robotic technology.

iXAPACK PACKAGING specializes in pouches overpack complete line design, manufacturing and installation. Flexible, ergonomics and above all high speed technologies.

Discover the iXAPACK fully automated turnkey lines enabling to handle pouches and doypack flows and to package them with our in-house manufactured equipment: Transit tunnel for Pasteurization and/or Cooling, Rack Loader/Unloader system for Autoclave, Weighing, Top Load Cartoning, Case Packing and Palletizing.

For more information on iXAPACK

© 2024 Alliedflex Technologies Inc. | Site by Longtail Digital